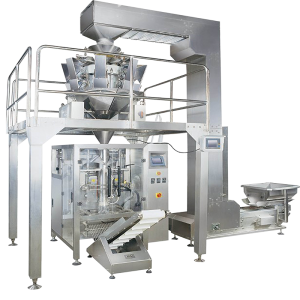

Tea bag packing machine Model : CP-520

Tea bag packing machine Model : CP-520

Working process:

1. Auto film finish making bag.

2. Printed production date.printer ribbon detection, printer ribbon stop alarm, touch screen display.

3. fill material.Detection:Material no fill, no heat seal.

4. Heat sealing.High Temperature heat sealing.

5. slitting

6. Sample output。

According to customer product configuration

Application:

| This production line is mainly composed of bag fully automatic packaging machine combined with electronic scales, bucket elevator, work platform supporting and become, is suitable for candy, nuts, raisins, peanuts, melon seeds, nuts, potato chips, chocolate, cookies and other big particles and sachet big bags, such as radix isatidis granule packing a big pack of automatic measurement. |

Main function

| 1.Reduce production costs and management costs: a packaging line reduces 4-10 workers, and input costs are recovered within 1-2 years |

| 2 Improve the quality of products: products from the appearance and packaging quality to achieve a unified standard |

| 3 To reduce the rate of defective products, the finished product rate is over 99.5%, and the waste of manual packaging is avoided. |

| 4 Improve hygiene standards: packaging process with no direct contact with people, to avoid human pollution |

Main properties and characteristics

| 1 Wide range of packaging: suitable for various states, properties of particles |

| 2 Easy operation: adopt PLC control, man-machine interface operating system, simple operation intuitionistic. |

| 3 Simple adjust: change variety in about ten minutes |

| 4 Suitable for different types of bags |

| 5Perfect prevention system to ensure product rate, no waste of bags and materials |

| 6 The machine packaging part is made of stainless steel material, which ensures the hygiene and safety of the material and conforms to the GMP standard. |

| 7High degree of automation: in weighing, packaging the whole process to achieve unmanned, failure automatic alarm |

| 8 Partial use of imported engineering plastics without refueling to reduce contamination of materials |

Configuration table

| Sequence NO. | Name of fitting | Country of origin | Brand |

| 1 | Touch screen | Germany | Siemens |

| 2 | PLC | Germany | Siemens |

| 3 | Servo motor including drive | Japan | Mitsubishi |

| 4 | Color standard sensorElectronic eye | China | Xinglong |

| 5 | Temperature control meter | China | Chaoneng |

| 6 | Horizontal sealing cylinder | Taiwan | Airtac |

| 7 | Vertical sealing with guide bar cylinder | Taiwan | Airtac |

| 8 | Cutter thin cylinder | Taiwan | Airtac |

| 9 | Push film cylinder | Taiwan | Airtac |

| 10 | Two couplet | Taiwan | Airtac |

| 11 | Value with gauge | Taiwan | Airtac |

| 12 | Electromagnetic valve with disc | Taiwan | Airtac |

| 13 | Inflatable solenoid valves | Taiwan | Airtac |

| 14 | Printer | China | Nan yun |

| 15 | Solid state relays | China | Yangming |

| 16 | Switching power supply | French | Schneide |

| 17 | Proximity switch | Taiwan | Rico |

| 18 | Button and indicator light | French | Schneide |

| 19 | breaker | French | Schneide |

| 20 | Intermediate relay | French | Schneide |

Parameter

| type | CP-520 |

| Max. Film width | Max.520mm |

| Bag length | 80-400mm |

| Bag width | 80-240mm |

| Packaging cubage | 1000ml |

| Packaging speed | 5-50bags/min |

| Packing thickness | 0.04-0.12mm |

| Power supply specification | 220V,4kw |

| Dimension | (L)1040x(W)1630x(H)1320mm |

| Total weight of machine | 500kg |

Note: because the equipment is continuously updated, if the parameters in the above table do not match the actual equipment parameters, please refer to the actual equipment parameters, or Consulting with company sales department.

Components:

| NO. | Item | Style | Specifications |

| 1 | Frame | 304 stainless appearance | |

| 2 | Cutting | high speed steel | |

| 3 | horizontal Seal mold | Chromium 12 conditioning | |

| 4 | Vertical Seal mold | Chromium 12 conditioning |

Equipment external dimensions

10-head electronic combination

|

The perfect combination of high precision and high speed is calculated by computer to select the best combination from the rich weight combination. |

|

The high precision digital weighing sensor can realize the accurate measurement instantaneous. |

|

Multilingual LCD operating system. |

|

According to characteristics of metered material, fine-tuning the opening and closing speed of hopper doors to prevent breakage and stop fill material. |

|

Strong data automatic statistics function, record the total number of each batch production, qualified rate and single bag error and other indicators. |

|

Selection device: smooth balance bucket, pattern scale bucket, collecting hopper, printing device, over differential sorting device. |

|

Strong compatibility, directly installed on the top of the packaging machine, more compact structure. |

|

Save you a lot of raw materials and labor costs, fast return on investment. |

|

Net weight:300Kg ;Gross weight:360Kg |

|

voltage:220V ;power:1500W;frequency:50/60HZ;rated current :9A |

|

outside dimensions (mm):斗bucket:1040×730×910mm Main machine:1090×1080×870mm=1.0242M3 |

Product parameters

|

application: all kinds of snack food, such as candy, melon seeds, potato chips, pistachios, fried seeds, nuts, preserved fruit, jelly |

|

Weighing packing.。 |

|

Single weighing range |

10-1000克 |

|

Single bag average error |

0.2-0.4克 |

|

Weighing precision range |

±0.1-2克 |

|

Maximum weighing speed |

60 bag/min |

|

Hopper capacity |

1300ml |

|

Driving mode |

stepper motor |

|

Product preset count |

99 kind |

|

Operation interface

|

Blue screen liquid crystal operating interface |

|

a) 。 Through computer calculation, the best weight combination is selected from the multi-group arrangement, which is superior to the intelligent and efficient weighing method of manual weighing. |

|

Weight hopper can be set in turn to prevent material blocking. |

|

Chinese / English and other language display system. |

|

Contact parts with materials using stainless steel, clean and sanitary. The full seal design prevents the material from piling up, and the cleaning is convenient. |

|

Can match the number of packaging machines for 1, with each other to achieve automatic weighing. |

|

Real-time display of each channel amplitude, better monitoring machine working state. |

|

The 99 groups of product parameters are stored in advance to meet the requirements of various parameter programs. |

Rotary bucket elevator

Specification

|

Power |

0.75kw |

|

delivery value |

6M³/H |

|

voltage |

220V/380V |

|

Gross weight |

560kg |

|

Height |

Depending on the customer’s needs |

Application

The hoist is suitable for vertical lifting of grain materials in grain, food, feed and chemical departments. Combined with computer balance and packaging machine combination quantitative automatic packaging system, widely used in food packaging industry.

Main performance and structural characteristics

The chain and fuselage are made of 304 stainless steel, the outer plate thickness is 1.5mm, the sprocket is made of industrial plastics, the lifting material plastics are mainly made of food grade polyacrylic PP, the capacity is 4L.

Working Platform

This platform is beautiful, strong, and has anti-slip surface platform, practical and safe. Made of stainless steel, the platform is 1.8 meters high, 2 meters long and clean. The main bearing computer combination scale, is the quantitative automatic packaging system an important supporting.